Sonic innoventor – World of Ultrasonic Power – Carpe frequentie

Theodor Storm Strasse 45

25821 Bredstedt

Germany

Innovations from Sonic innoventor

Anyone who claims that it is not possible must learn not to interrupt someone who is actually doing it.

Relaiability from Sonic innoventor

Our creativity is restricted merely by our assumptions.

Commitment of Sonic innoventor

I’m helping my colleagues to realize that they are winners.

Good Humour at Sonic innoventor

The shortest distance between people is a smile.

Multi Frequency Generators “MFG”

Sonic innoventor was formed 2006, but with combined 40 years of experience.

We are able to supply high quality solution within:

Multi Frequency Generators “MFG”

The World of Ultrasonic horns

The device is necessary because the ultrasonic amplitudes provided by the ultrasonic transducers them selves are insufficient for most practical applications of power ultrasound.

We are able to supply high quality solution within

Multi Frequency Generators “MFG”

Our ultrasonic Generators are able to run any frequency 15 kHz, 20 kHz, 22 kHz, 23 kHz, 25 kHz, 28 kHz, 30 kHz, 35 kHz, 36 kHz, 40 kHz and so on up to our maximum standard today 150 kHz, since it is a true multi frequency ultrasonic generator, any frequency can be set on our ultrasonic generator.

- Generator

- Boosters

- Hand-Pistols

- Horns–Sonotrodes

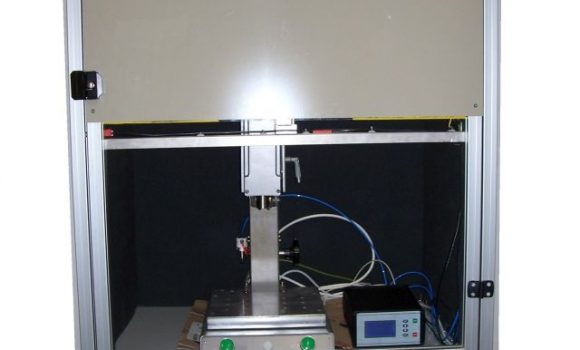

- Metal-Welding-presses

- Converter

- Ultrasonic-Sewing-Machines

- Ultrasonic-performance-and-controller

- Sonoreactor

Multi Frequency Generators “MFG”

Our ultrasonic Generators are able to run any frequency 15 kHz, 20 kHz, 22 kHz, 23 kHz, 25 kHz, 28 kHz, 30 kHz, 35 kHz, 36 kHz, 40 kHz and so on up to our maximum standard today 150 kHz, since it is a true multi frequency ultrasonic generator, any frequency can be set on our ultrasonic generators.

In general term the Ultrasonic generator converts the 50-60 Hz (1 Hz is one electrical movement) in the power line system into ultra frequency levels. These frequencies are normal from 15 kHz to 100 kHz, within the ultrasonic power systems.

An Ultrasonic power signal generator, produces a certain frequency sinusoidal (or similar sinusoidal) signals, to drive the ultrasonic Transducer – ultrasonic booster and ultrasonic Horn also known as stack.

The Ultrasonic transducer converts the sinus signal from the ultrasonic generator into mechanical vibrations, which then in return vibrates with the desired ultrasonic stack frequency.

Ultrasonic generators comes under following names:

Ultrasonic welding Generator, Ultraschall schweiss generator, Ultraschall schweissgenerator, Ultraschallgeneratoren, Ultrasonic Generator, UltraschallGenerator, Ultraschall generator, Generador de ultrasonidos, Gerador de ultra-som, Ultrasonic Cutting Generator, Ultraschall generatoren, Ультразвуковой генератор сварочный, Ultradźwiękowy Generatory spawanie, Générateur de soudage par ultrasons, Générateur à ultrasons coupe l’alimentation, Ultrasonic food cutting Generator, Ultradźwiękowy Generatory cięcie żywności, Ультразвуковой генератор резки пищи, Générateur de soudage par ultrasons, ultrasonic welding generator, saldatura generatore di ultrasuoni, Ultradźwiękowy generatory spawalniczy, gerador de soldagem ultra-sônica, ультразвуковой генератор сварочный, generador de soldadura por ultrasonidos,

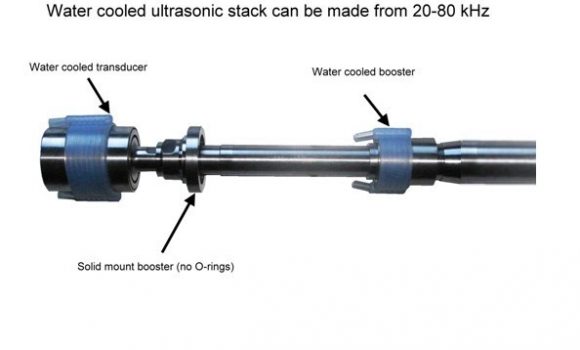

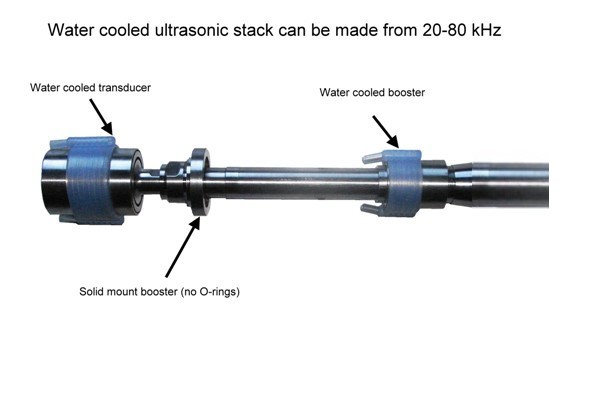

General Description of ultrasonic Booster:

Email : info@sonic-power.com

The Ultrasonic Booster is like the gear in a car, where as the lowest is first gear and so forward. This also means that the higher ultrasonic booster you put on the more power is needed behind to start it, so even if the ultrasonic horn can take more gain (higher ratio), if you ultrasonic generator is not powerfully enough you will not be able to start it up and the Ultrasonic generator will go into overload.

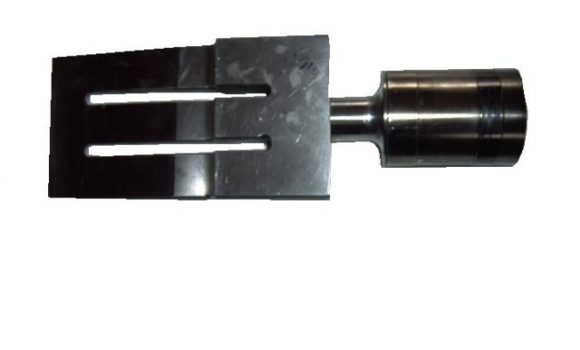

The Ultrasonic booster is a one half-wavelength long resonant section made of aluminium or titanium. It is mounted between the Ultrasonic converter and the Ultrasonic horn, and modifies the amplitude of vibration applied to the Ultrasonic horn.

The success of an ultrasonic plastics assembly application is dependent on the required force, time, and velocity factor to obtain the correct energy level. The ultrasonic velocity factor is obtained by using the correct ultrasonic horn and ultrasonic booster combination to provide the optimum amplitude for the type of plastic, size of part, and type of assembly to be per-formed. Since it may be technically impractical to design the correct amplitude into the ultrasonic horn because of its shape, ultrasonic boosters are used to either increase or decrease the amplitude at the ultrasonic horn face to transmit the required energy to the joint interface.

To provide amplitude change, the ultrasonic booster will have different diameters and mass on either side of its centre or nodal point.

An amplitude increasing booster has a smaller mass at the end attached to the ultrasonic horn, while an amplitude decreasing ultrasonic booster has a greater mass at the end attached to the ultrasonic horn.

Choosing the Correct ultrasonic Booster: When selecting a ultrasonic booster to be used for an application, it is recommended to use the lowest gain ratio possible that will provide acceptable application results for correct amplitudes values. This will help to operate the ultrasonic horns at lower fatigue levels, which increases tooling reliability.

Ultrasonic horns are designed to be operated with a maximum ultrasonic booster limitation so they will not exceed unreliable fatigue stress levels. The maximum ultrasonic booster limits for special ultrasonic horns are etched directly on the ultrasonic horn along with the horn identification numbers.

Types and Mounting of Ultrasonic Boosters: Ultrasonic Boosters are clamped at their nodal point and provide rigid support for the ultrasonic converter / ultrasonic booster / ultrasonic horn assembly.

There are three types of ultrasonic boosters with different mounting systems: 1) standard mount; 2) rigid mount with square O-rings and removable clamp rings (which also is repairable); and 3) solid mount that provide improved rigidity. For continuous applications, solid mount ultrasonic boosters deliver more energy to the product, while in plunge applications, improved alignment is possible. For more information on solid mount boost.

On the ultrasonic converter / ultrasonic booster / ultrasonic horn stack should use o-ring ultrasonic boosters, as they absorb some of the side loads which would otherwise lead to premature failure of the ultrasonic horn in the stud area.

Stud Sizes:

Aluminium 15 – 20 – 25 kHz ultrasonic boosters with ratios of 1:0.6, 1:1, 1:1.5, and 1:2 are available with the ultrasonic horn end drilled and tapped either 1/2-20 or 3/8- 24. Titanium 15 – 20 – 25 kHz boosters in all ratios, including 1:2.5, are available with 1/2-20 or 3/8-24 tap. ultrasonic Boosters for 30 – 35 – 36 – 40 kHz are available with the ultrasonic horn end drilled and tapped for M-8 threads.

Ultrasonic Boosters are available with ratios of 1:0.5, 1:1, 1:1.5, 1:2, 1:2.5 and 1:3.0

Calculating Gain and Its Effects:

Calculation of ultrasonic converter / ultrasonic booster / ultrasonic horn stack gain, and how ultrasonic booster gain affects the total gain.

To further illustrate the effects of gain, a high amplitude ultrasonic horn might be compared to fifth gear in a car which produces high speed and low torque. Conversely, a low-amplitude ultrasonic horn – similar to first gear.

Ultrasonic Booster which produces low speed and high torque – has tremendous force capabilities and will vibrate under hundreds of pounds of load. It is relatively easy to “stall” a high-amplitude ultrasonic horn by operating it at high forces, just as it would be to stall a car motor starting up a steep hill in third gear. Each ultrasonic horn / ultrasonic booster combination must be tailored to the specific application to optimize performance.

General Description of ultrasonic Booster:

Ultrasonic boosters comes under following names:

Ultrasonic Booster, Ultraschall booster, ultrassons booster, ultraschall Übersetzungsstück, Ultrasonic velocity transformer, ultraschall Amplituden transformations stuck, Ultrasons Booster, ultradźwiękowy Booster, Booster ultrasuoni, Impulsionador ultra-sônica, Ультразвуковые ракета–носитель, Booster ultrasonidos, El Booster ultrasonidos, ultrasonique booster, ultrasonique booster, ultradźwiękowy falowód,

Ultrasonic Hand pistols

Email : info@sonic-power.com

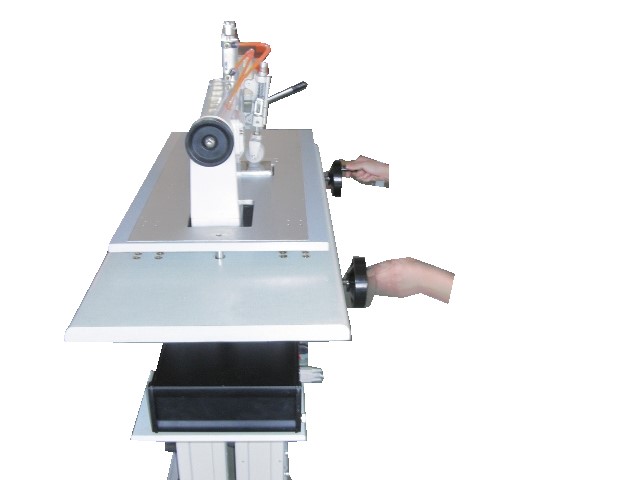

Ultrasonic handpistol are one of the simplest ways to do ultrasonic welding, Ultrasonic cutting ect, but can at the same time also be one of the most complicated, depending on the application.

It is easy to do test with, making ultrasonic hair extension, ultrasonic welding parts together without energy director and doing cutting of all kinds of materials.

Ultrasonic Hand welders comes under following names:

Ultrasonic Slicer, Ultrasonic Slicing, Coupe l’alimentation par ultrasons, De découpe par ultrasons, Ultrasonic Carpet cutting, Ultrasonic Tyre Cutting, Ultrasonic Tire Cutting, Ultrasonic Textile cutting, Ultrasonic Fabric Cutting, Ultrasonic Hand Gun, Ultrasonic Hand Welder, Ultrasonic Hand Cutter, Ultrasonic Hand Welding, Ultrasonic Hand Slicing, Ultrasonic Hand Slicer, Coupe Tyr, Ultraschall heiss messern, ultrasonic hot knife ultrasons, UltrasonicTextile coupe, Couper des tissus par ultrasons, Gun à la main à ultrasons, Soudeur à la main à ultrasons, Cutter à la main à ultrasons, Soudage à la main à ultrasons, Main à ultrasons à trancher, Slicer main à ultrasons, Ultradźwiękowy cięcia opon, UltrasonicTextile cięcia, Ultradźwiękowy cięcia tkanin, Ultradźwiękowy Gun rąk, Ultradźwiękowy Zgrzewarka ręczna, Ultradźwiękowy Cutter rąk, Spawanie ultradźwiękowe rąk, Ultradźwiękowy rąk Odcinanie, Ultradźwiękowy Krajalnica ręczna, Ultraschall Reifen Schneiden, UltrasonicTextile Schneiden, Ultraschall-Fabric Schneiden, Ultraschall-Hand Gun, Ultraschall-Handschweißgerät, Ultraschall-Hand-Cutter, Ultraschall-Hand Schweißen, Ultraschall-Hand-Slicing, Ultraschall-Hand-Schneidemaschine, Tiro di taglio ad ultrasuoni, UltrasonicTextile taglio, Tessuto di taglio ad ultrasuoni, Mano Gun ultrasuoni, Mano saldatore ad ultrasuoni, Mano Cutter a ultrasuoni, Mano saldatura a ultrasuoni, Mano ultrasuoni affettatura, Mano Slicer ultrasuoni, Ультразвуковой резки шин, Ultrasonic Textile резки,Ультразвуковая резка ткани, Ультразвуковой пистолет, Ультразвуковой сварки рук, Ультразвуковые Cutter рук,Ультразвуковая сварка рук, Ультразвуковые рук нарезки, Ультразвуковые Slicer рук, Ultrasonic Tyre Cutting horn, Ultrasonic Tyre Cutting sonotrode,Sonotrode coupe Tyr, Ultradźwiękowy róg cięcia opon, Ultrasons sonotrode coupe Tyr, Ultrasuoni Tyre sonotrodo taglio, Ultradźwiękowy Sonotroda cięcia opon, Sonotrodo corte ultra-sônico Tiro, Ультразвуковой волновод резки шин, Tiro sonotrodo ultrasónico de corte, Ultraschall Reifen schneiden Sonotrode, Heiß ultraschall Messern, hot ultrasonic knife, chaude bistouri à ultrasons, coltello caldo ad ultrasuoni, gorący nóż ultradźwiękowy, bisturi ultra-quente, горячий ультразвуковой нож, cuchillo ultrasónico caliente, Heiß Ultraschallmesser, Ultrasonic welding and cutting, ultrasonic welding and sealing, Schneidsonotroden, weld and cut, weld and seal, Ultraschall-Schweißen und Schneiden, Ultraschall-Schweißen und versiegeln, ультразвуковой сварки и вырезать, ультразвуковой сварки и печатью, soldadura ultrasónica y corte, soldadura ultrasónica y el sello, ultradźwiękowego spawania i cięcia, spawania ultradźwiękowego i pieczęć, saldatura ultrasonica e taglio, saldatura ad ultrasuoni e di tenuta, soudure par ultrasons et couper, souder par ultrasons et d’étanchéité, sonic vibratory knife blade,

The World of Ultrasonic horns – Sonotrodes

Email : info@sonic-power.com

The World of Ultrasonic horns

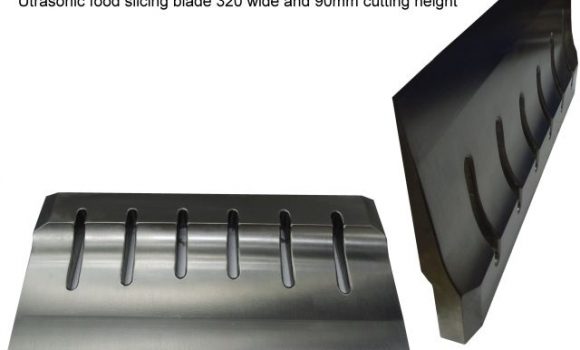

Ultrasonic horns is a device commonly used for augmenting the oscillation displacement amplitude provided by an ultrasonic transducer operating at the low end of the ultrasonic frequency spectrum (commonly between 15 and 100 kHz).

The device is necessary because the ultrasonic amplitudes provided by the ultrasonic transducers them selves are insufficient for most practical applications of power ultrasound.

Another function of the ultrasonic horn is to efficiently transfer the acoustic ultrasonic energy from the ultrasonic transducer into the treated media, which may be solid for example, in ultrasonic welding, cutting or soldering or liquid.

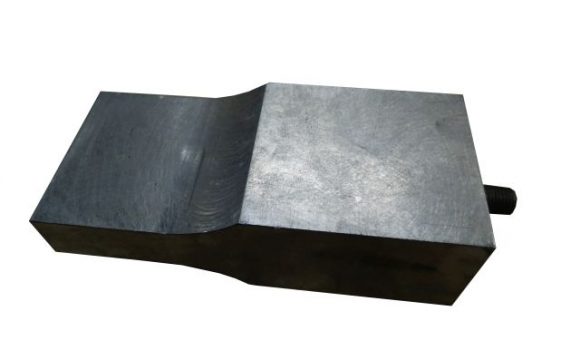

The ultrasonic horn is commonly a solid metal rod with a round transverse cross-section and a variable-shape longitudinal cross-section – the ultrasonic rod horn. Another group includes the ultrasonic block horn, which has a large rectangular transverse cross-section and a variable-shape longitudinal cross-section, and more complex composite horns. The devices from this group are used with solid treated media. The length of the device must be such that there is mechanical resonance at the desired ultrasonic frequency of operation – one or multiple half wavelengths of ultrasound in the horn material, with sound speed dependence on the ultrasonic horn’s cross-section taken into account. In a common assembly, the ultrasonic horn is rigidly connected to the ultrasonic transducer using a threaded stud.

Ultrasonic horns may be classified by the following main features: Longitudinal cross-section shape – stepped, exponential, conical, catenoidal, Transverse cross-section shape – round, rectangular, Number of elements with different longitudinal cross-section profile – common and composite.

A composite ultrasonic horn has a transitional section with a certain longitudinal cross-section shape (non-cylindrical), positioned between cylindrical sections.

Frequently, an ultrasonic horn has a transitional section with a longitudinal cross-section profile that converges towards the output end. Thus, the ultrasonic horn’s longitudinal oscillation amplitude increases towards the output end, while the area of its transverse cross-section decreases. Ultrasonic horns of this type are used primarily as parts of various ultrasonic instruments for ultrasonic welding, soldering, cutting, making surgical tools, molten metal treatment, etc. Converging ultrasonic horns are also commonly included in laboratory liquid processors used for a variety of process studies, including ultrasonic sonochemical, ultrasonic emulsification, ultrasonic dispersing and many others.

Maximum achievable ultrasonic amplitude depends, primarily, on the properties of the material from which an ultrasonic horn is made as well as on the shape of its longitudinal cross-section. Commonly, the horns are made from titanium alloys, such as Ti6Al4V, aluminium alloys or powdered metals. The most common and simple to make transitional section shapes are conical and catenoidal.

(, also known as: Ultrasonic Sonotrode, ultradźwiękowy narzedzia, sonotrodi ultrasuoni, Ultrasonic welding Sonotrode, ultrasonique sonotrode, Ultrasonic Horn, Ultraschall sonotrodes, Ultraschall sonotroden, ultrasonique sonotrode, Ultraschallsonotrode, Ultraschall sonotrode, Sonotroden, ultrasonic Sonotrodes, Ultraschallsonotroden, Ultrasonic composite Sonotrode, Ultraschall Komposit Sonotroden,Sonotrodes, Sonotrode, sonotrody ultradźwiękowe, Horn, Ultrasonic Blade, Ultrasonic Sonotrodes, Ultrasonic Welding horn, Ultrasonic Sonotrode, Sonotrodes ultra-som, Ультразвуковые сонотродов, Sonotrodes ultrasons, Ultrasonic Welding sonotrode, Ultraschall-Schweißen Sonotrode, Sonotrodo de soldadura por ultrasonidos, Ультразвуковая сварка волновод, Sonotrodo soldagem ultra-som, Ultradźwiękowy Sonotroda Spawanie, Saldatura a ultrasuoni sonotrodo, Sonotrode de soudage par ultrasons, Sonotrode ultrasons, Ultrasonic Tyre Cutting Horn, Ultrasonic Tire Cutting Horn, ultrasonic blade, Ultradźwiękowy sonotrody, Sonotrode de soudage par ultrasons, Sonotrodo soldagem ultra-som, Sonotrodo de soldadura por ultrasonidos, Sonotrode ultrasons, Ультразвуковые сонотродов, Sonotrodes ultra-som, Ultrasonic Welding horn, Sonotroden, Sonotrodes, Ultrasonic Sonotrodes, ultraschall schneid sonotrode, ultraschall Schneidsonotrode, Schneidsonotrode, ultrasonic composite horn)

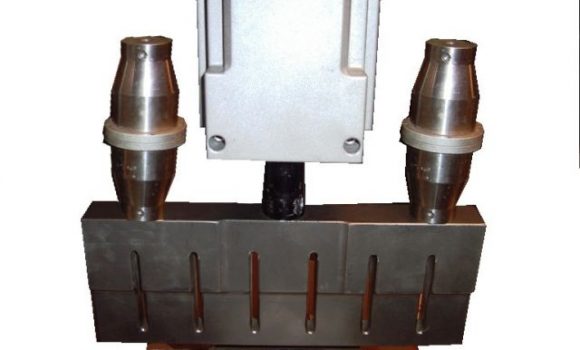

Ultrasonic Metal welding systems are composed of the same basic elements:

Email : info@sonic-power.com

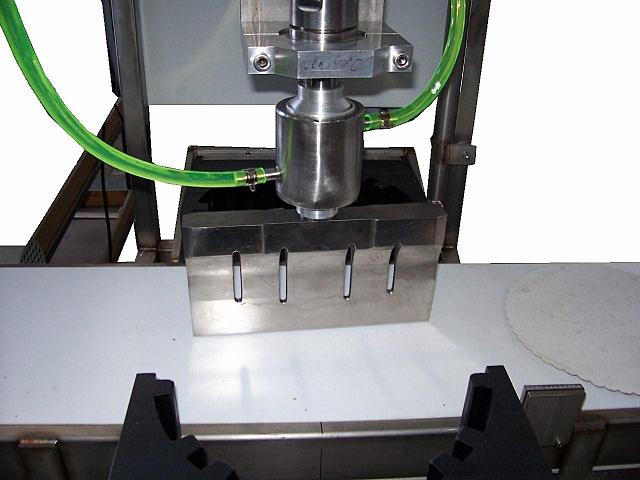

A Ultrasonic press to put the two parts to be ultrasonic assembled under pressure, the press can be:

to be able to have a controlled moment for the ultrasonic process, like Ultrasonic Metal Welding, Ultrasonic Metal Cutting, Solar panel welder Ultrasonic rotating metal welder ect. and are in 98% of the times used direct Horizontal on the part.

A ultrasonic nest or ultrasonic anvil where the parts are placed and allowing the high frequency ultrasonic vibration to be directed to the interfaces

An ultrasonic stack composed of a ultrasonic converter or ultrasonic piezoelectric transducer, an optional ultrasonic booster and a ultrasonic sonotrode, Horn.

All three elements of the ultrasonic stack are specifically tuned to resonate at the same exact ultrasonic frequency (Typically 15, 20, 25, 30, 35 or 40 kHz)

Converter: Converts the electrical signal into a mechanical ultrasonic vibration

Ultrasonic Booster: Modifies the amplitude of the vibration. It is also used in standard systems to clamp the ultrasonic stack in the ultrasonic press.

Ultrasonic Sonotrode – Horn: Applies the mechanical vibration to the parts to be welded.

An electronic ultrasonic generator (US: Power supply) delivering a high power AC signal with frequency matching the ultrasonic resonance frequency of the stack.

A controller controlling the movement of the press and the delivery of the ultrasonic energy.

Ultrasonic Metal Welding,

Ultraschall metall schweissen,

Soudage à ultrasons

Saldatura dei metalli ad ultrasuoni

超声波金属焊接

Spawanie ultradźwiękowe Metal

Soldagem ultra-sônica

Ультразвуковая сварка металлов

Soldadura de metales por ultrasonidos

Ultrasonic welding press, Ultraschallschweiss presse, Ultraschallschweisspresse, Presse soudere ultrasons, Presse souder ultrasons, Thruster, Schweißgerät, Ultraschall Schweißpresse, Ultraschall Kunststoff Schweißgerät, Vorschubeinheit, Vorschub einheit, Servopress, Servopressen, Servo Press, Servo Pressen, Ultraschall metallschweissen, Ultraschall metall schweissen, Soudage par ultrasons, Ultrasonic Solar panel welder Ultrasonic rotating metal welder,ultrasons soudeur panneau solaire, saldatrice ad ultrasuoni pannello solare, ultradźwiękowy słoneczny spawacz panel, soldador painel de energia solar ultra-sônica, ультразвуковых солнечных панелей сварщик, soldadura ultrasónica de paneles solares, Ultraschall Solar panel Schweißer,Ultraschall Metall Schweißer, soldador de metal por ultrasonidos, ультразвуковых сварочный металл, soldador de metal ultra-som, ultradźwiękowy spawacz metalu, ultradźwiękowy spawacz metalu, metallo saldatore ad ultrasuoni, soudeur métallique ultrasons,

But all of the above names serves the same purpose,

Ultrasonic transducer – Converter

Email : info@sonic-power.com

An ultrasonic transducer is a device that converts electrical ultrasonic energy into ultrasound energy, or sound waves above the normal range of human hearing. While technically a dog whistle is an ultrasonic transducer that converts ultrasonic mechanical energy in the form of air pressure into ultrasonic sound waves, the term is more apt to be used to refer to ultrasonic piezoelectric transducers that convert electrical energy into ultrasound.

Piezoelectric crystals have the property of changing size when a voltage is applied, thus applying an alternating current (AC) across them causes them to oscillate at very high frequencies, thus producing very high ultrasonic frequency sound waves.

The location at which a ultrasonic transducer focuses the ultrasound can be determined by the active ultrasonic transducer area and shape, the ultrasound frequency, and the ultrasonic sound velocity of the propagation medium.

Ultrasonic transducer

Ultrasonic converters, as an inevitable Frontend of all ultrasonic systems serve the electro mechanical energy conversion. They transform the electric oscillations in mechanical waves or vice versa and form with it the interface between signal processing and measuring section. On account of the high efficiency Piezo ceramics, e.g., from lead-zirconate-titanate as a key component of the ultrasonic converter often become elective.

In addition, the electric-acoustic conversion properties are decisively influenced by her mechanical construction, the well-chosen materials, and the used connection technologies (gluing, soldering, cleaning, welding). On account of the complicated coupling as well as the reaction between electric and mechanical dimensions, an analytic description or optimization of the sound converter is extremely sophisticated. On the other hand, the application specific optimization of the ultrasonic transducer shows the biggest potential concerning functionality and costs of an ultrasonic welding system.

We are offering following services:

• Analysis of the requirements for the ultrasonic converter from view point of the technical demands, the environment conditions, the costs and the manufacturing technology.

• Identification and interpretation of suitable ultrasonic transducers technologies for ultrasonic de-gases, ultrasonic welding and liquids and ultrasonic application in lab, ultrasonic industry, automotives and consumer products.

• Optimization of ultrasound converters with the help of simulation models (FEA).

• Production of experimental models and prototypes.

• Electric-acoustic characterization of ultrasonic transducers and specification of the necessary components.

• Production of prototype series as well as support concerning suitable production technology including quality assurance and the manufacturing introduction.

• OEM delivery of complete ultrasonic transducers.

Technical skills

Special experiences from high power developments in the automotive-area (level, media qualities) as well as from industrial applications (ultrasonic welding, Ultrasonic Cleaning,) in welding phase and liquid phase allow the purposeful solution of your developing task within a given high-class frame and cost frame to us.

Ultrasonic Transducers comes under following names:

Ultrasonic transducer, Ultrasonic converter, Ultraschall converter, Ultraschall wandler, Ultraschall konvertern, Convertisseur à ultrasons, Transducteur à ultrasons, Ультразвуковой датчик, Ультразвуковой преобразователь, Transdutor de ultra-som, Conversor de ultra-som, przetwornik ultradźwiękowy, transdutor de ultra-som, Ультразвуковой датчик, trasduttore ad ultrasuoni, transductor ultrasónico, convertidor ultrasónico, conversor de ultra-som, Convertitore di ultrasuoni, Transducteur d’ultrasons, ultradźwiękowy przetwornik, Ultraschallschweißen Konverter, transductor soldadura ultrasónica, ультразвуковой датчик сварки, transdutor soldadura ultra-sónica, przetwornik ultradźwiękowy spawanie, saldatura trasduttore a ultrasuoni, Transducteur de soudage par ultrasons, Convertisseur de soudage par ultrasons, convertitore di saldatura ad ultrasuoni, Ultradźwiękowy przetwornik spawanie, conversor soldadura ultra-sónica, Преобразователь ультразвуковой сварки, convertidor soldadura ultrasónica, ultrasonic welding converter, ultrasonic welding transducer, del convertidor, liquid cooled converter,

Sound of silence, rotating ultrasonic sewing machines and ultrasonic textile cutter.

Email : info@sonic-power.com

Ultrasonic sewing machines comes in many designs, but common for most of the they are made with 20 kHz, and operator that is using them are them exposed for the high sound level and thereby hearing loos over time.

We have developed our ultrasonic sewing machines from 25 kHz and up and thereby no hearing sound or uncomfortable feeling when using them.

The advantage are also that do to the higher ultrasonic frequency you are also able to weld faster and weld material that you are not able to weld with 20 kHz.

Our vertical ultrasonic sewing machine are able to ultrasonic weld PVC up to 2mm thick and 40mm wide, for tarpaulins for trucks, this is never seen before with ultrasonic and speed up to 25 meters per minute, without burning the PVC.

Ultrasonic Sewing welders comes under following names:

Ultrasonic sewing machine, Ultrasonic sewingmachine, Ultraschallnähmaschine, Ultraschall Nähmaschine, Ultrasonic cutter, ultraschall textile schneidern, Machine à coudre à ultrasons, Máquina de costura ultra-sônica, Ultradźwiękowe maszyny do szycia, Ультразвуковые швейные машины, Máquina de coser por ultrasonidos, Macchina da cucire ad ultrasuoni, Ultrasonic Cut and seal, Tagliare ultrasuoni e guarnizione, Corte ultrasónico y el sello, Ультразвуковые и печать, cortar ultra-sônico e selo, Ultradźwiękowy cięcie i pieczęć, couper ultrasons et le joint, ultraschall schneiden und versiegeln,

High Power ultrasonic Sonoreactors

Email : info@sonic-power.com

The ultrasound science and ultrasound technology are becoming a growing research field because of a wide range of emerging applications in ultrasonic chemical synthesis, ultrasonic therapeutics, ultrasonic environmental protection, ultrasonic electrochemistry, ultrasonic processing of food, ultrasonic processing of solids and liquids. However, it has been stressed in literature the difficulty of the development of the scale-up strategies from laboratory to industrial scale particularly in the ultrasonic sonoreactor design.

Several causes have been highlighted such as: marked effects localized near the surface of the ultrasonic sonicator non-uniform and non-optimized volumetric energy density erosion of the ultrasonic horn surface at high power intensities and a perfectible ultrasonic transducer technology. At this stage, it is very important to characterize the behaviour of ultrasonic sonoreactors in order to identify accurately the actives zones, especially those related to the ultrasonic cavitations events, as well as it might also shed light on an accurate picture on the reaction environment in the ultrasonic sonoreactor.

On the other hand, attention is being paid on the subdivision of the ultrasonic sonochemical applications based on the “true” and “false” effects Several differences are established between the chemical effects (resulting from the ultrasonic cavitation event) and the effects caused by the ultrasonic mechanical actions (mainly as a consequence of the bubble collapse) Regarding the above subdivision, we can find in the ultrasonic literature a large number of methods, and also classifications of them which characterize the ultrasonic sonoreactor behaviour. These analyses have been devised to measure the effects of ultrasound especially the ultrasonic power, but recently there is a increasing number of papers studying the ultrasonic mechanical effects including modelling techniques

Classical methods designed for ultrasonic mechanical effect studies use hydrophones aluminium foil erosion and thermistors and thermoelectrical probes for local measurements and the calorimetric method for global ultrasonic measurements.

Recent Products

In general term the Ultrasonic generator converts the 50-60 Hz (1 Hz is one electrical movement) in the power line system into ultra frequency levels. These frequencies are normal from 15 kHz to 100 kHz, within the ultrasonic power systems.

GET A QUICK QUOTE

Sonic Innoventor is a company with talented professional team, ready to answer any question you might have.