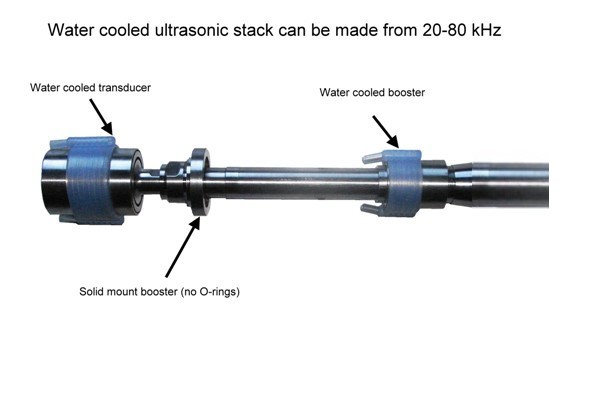

We have designed a water cooled transducer and booster to be able to run in temperatures up you 300 Celsius, without destroy the transducer, special for ultrasonic atomizing

General Description of ultrasonic Booster:

Email : info@sonic-power.com

The Ultrasonic Booster is like the gear in a car, where as the lowest is first gear and so forward. This also means that the higher ultrasonic booster you put on the more power is needed behind to start it, so even if the ultrasonic horn can take more gain (higher ratio), if you ultrasonic generator is not powerfully enough you will not be able to start it up and the Ultrasonic generator will go into overload.

The Ultrasonic booster is a one half-wavelength long resonant section made of aluminium or titanium. It is mounted between the Ultrasonic converter and the Ultrasonic horn, and modifies the amplitude of vibration applied to the Ultrasonic horn.

The success of an ultrasonic plastics assembly application is dependent on the required force, time, and velocity factor to obtain the correct energy level. The ultrasonic velocity factor is obtained by using the correct ultrasonic horn and ultrasonic booster combination to provide the optimum amplitude for the type of plastic, size of part, and type of assembly to be per-formed. Since it may be technically impractical to design the correct amplitude into the ultrasonic horn because of its shape, ultrasonic boosters are used to either increase or decrease the amplitude at the ultrasonic horn face to transmit the required energy to the joint interface.

To provide amplitude change, the ultrasonic booster will have different diameters and mass on either side of its centre or nodal point.

An amplitude increasing booster has a smaller mass at the end attached to the ultrasonic horn, while an amplitude decreasing ultrasonic booster has a greater mass at the end attached to the ultrasonic horn.

Choosing the Correct ultrasonic Booster: When selecting a ultrasonic booster to be used for an application, it is recommended to use the lowest gain ratio possible that will provide acceptable application results for correct amplitudes values. This will help to operate the ultrasonic horns at lower fatigue levels, which increases tooling reliability.

Ultrasonic horns are designed to be operated with a maximum ultrasonic booster limitation so they will not exceed unreliable fatigue stress levels. The maximum ultrasonic booster limits for special ultrasonic horns are etched directly on the ultrasonic horn along with the horn identification numbers.

Types and Mounting of Ultrasonic Boosters: Ultrasonic Boosters are clamped at their nodal point and provide rigid support for the ultrasonic converter / ultrasonic booster / ultrasonic horn assembly.

There are three types of ultrasonic boosters with different mounting systems:

1) standard mount; 2) rigid mount with square O-rings and removable clamp rings (which also is repairable); and 3) solid mount that provide improved rigidity. For continuous applications, solid mount ultrasonic boosters deliver more energy to the product, while in plunge applications, improved alignment is possible. For more information on solid mount boost.

On the ultrasonic converter / ultrasonic booster / ultrasonic horn stack should use o-ring ultrasonic boosters, as they absorb some of the side loads which would otherwise lead to premature failure of the ultrasonic horn in the stud area.

Stud Sizes:

Aluminium 15 – 20 – 25 kHz ultrasonic boosters with ratios of 1:0.6, 1:1, 1:1.5, and 1:2 are available with the ultrasonic horn end drilled and tapped either 1/2-20 or 3/8- 24. Titanium 15 – 20 – 25 kHz boosters in all ratios, including 1:2.5, are available with 1/2-20 or 3/8-24 tap. ultrasonic Boosters for 30 – 35 – 36 – 40 kHz are available with the ultrasonic horn end drilled and tapped for M-8 threads.

Ultrasonic Boosters are available with ratios of 1:0.5, 1:1, 1:1.5, 1:2, 1:2.5 and 1:3.0

Calculating Gain and Its Effects:

Calculation of ultrasonic converter / ultrasonic booster / ultrasonic horn stack gain, and how ultrasonic booster gain affects the total gain.

To further illustrate the effects of gain, a high amplitude ultrasonic horn might be compared to fifth gear in a car which produces high speed and low torque. Conversely, a low-amplitude ultrasonic horn – similar to first gear.

Ultrasonic Booster which produces low speed and high torque – has tremendous force capabilities and will vibrate under hundreds of pounds of load. It is relatively easy to “stall” a high-amplitude ultrasonic horn by operating it at high forces, just as it would be to stall a car motor starting up a steep hill in third gear. Each ultrasonic horn / ultrasonic booster combination must be tailored to the specific application to optimize performance.

General Description of ultrasonic Booster:

Ultrasonic boosters comes under following names:

Ultrasonic Booster, Ultraschall booster, ultrassons booster, ultraschall Übersetzungsstück, Ultrasonic velocity transformer, ultraschall Amplituden transformations stuck, Ultrasons Booster, ultradźwiękowy Booster, Booster ultrasuoni, Impulsionador ultra-sônica, Ультразвуковые ракета-носитель, Booster ultrasonidos, El Booster ultrasonidos, ultrasonique booster, ultrasonique booster, ultradźwiękowy falowód,

Leave a Reply

You must be logged in to post a comment.